Assistance and Warranty

Italian Warranty on all items

Compressors and accessories sold on www.cabex.eu are all products destined for the Italian market, unless otherwise specified on the product page.

The customer can therefore make use of the ITALIAN WARRANTY, the duration of which is specified in the appropriate documentation inside the package (this documentation may not be available at the discretion of the manufacturer), as well as the 24-month warranty against conformity defects in accordance with Leg. Decree 206/05. The purchase receipt enclosed with the product must be kept in order to utilise the warranty.

Advantages of the Italian warranty

Faster service: customers can contact the authorised service centre in Italy, if specified on the certificate, without having to ship the product to www.cabex.eu, thus shortening troubleshooting times.

After-sales assistance

If a problem arises with a product purchased, it is best to report it immediately to our customer service by sending an e-mail from the contact section of www.cabex.eu.

If you need to make use of the warranty service, we always advise you to first contact our service department, which will advise you on which authorised service centre to send the product.

If the customer is unable to send the product to the notified service centre, CABEX. CO. S.r.l. shall send the product on behalf of the customer. In these cases (including for items still under warranty), shipping costs will be borne by the customer.

Assistance times vary in this case depending on the manufacturer/service centre but are never less than 30 days. Our operators are also available for any clarification regarding product operation or features. In this case, we would advise you to contact us by mail so that the operator can take the time necessary for a complete answer.

Tips for choosing a compressor

It can be difficult to decide which is the right model for you, with so many different ones on the market.

When might I need a compressor?

Air, like any other gas, can be compressed (the air volume is reduced with consequent pressure increase) to become a useful source of energy, thanks to the pressure generated by the compression.

A compressor lets you: clean, blow, wash, inflate, paint, power various types of pneumatic tools

Which model should I choose?

There are different types of compressors and each one has its own characteristics:

a) Coaxial direct compressors

In these models, the engine, which has a rotation speed of about 3,000 rpm, is connected directly to the shaft of the characteristic pumping unit which, in addition to reducing the encumbrance, eliminates all types of power loss. They are less expensive, easier to handle and especially suitable for occasional and sporadic DIY and household use. The pressure reached by these compressors never exceeds 8 bars, while their power is usually between 1.5 and 3 Hp with air intake ranging from 130 to 340 L/min.

Coaxial compressors are divided into the following types:

Oil-free (without lubrication)

They do not release any oil particle

s with the air supplied, as instead happens with oil-lubricated models. They are suitable for use for example in the medical, dental, and nutrition fields, but are also suitable for airbrushing or painting.

Oil (lubricated)

Oil (lubricated)

These are longer lasting than the Oil-Free compressors since the damage caused by friction is cancelled out by the fact that the pistons have an oil bath lubrication. They are usually quieter and more powerful, and are especially applicable in craft and industrial sectors.

b) Belt compressors

In belt compressors, the motor is connected to the pumping unit by means of a drive belt which, rolling on the pulleys, provides power to the pumping unit. The motor rotation speed (about 2,400/3,000 rpm) is always higher than that of the pumping unit and this results in greater silence, longer pumping unit life, but above all higher performance as the torque value is greatly increased. These compressors also offer the advantage of working effortlessly and without loss of power even during the recharging phase as they can collect air quickly. SILENCED single-stage and two-stage belt compressors also exist for greater operator comfort while maintaining the same level of performance. These models in fact have a soundproof cover but, above all, their motors have a significantly reduced rotation speed. The pressure that the belt compressors reach is usually 8-10 bar but there are special models for high pressure operation that even reach 15 bar.

Belt compressors are divided into the following types:

Single-belt

equipped with pistons of the same diameter in which air compression takes place in a single phase.

They can be SINGLE-CYLINDERS (with 1 piston) or TWO-CYLINDER (with 2 pistons) with a power varying from 2 to 4 Hp and an air intake value of between 250 and 490 L/min.

Two-stage

equipped with 2 pistons, in which air compression occurs with 2 pressure jumps so that the compression work is reduced and a lower compressed air temperature is obtained. In fact, air is cooled by a pipe or by means of a finned manifold between one compression phase and another (i.e. before the air enters the second piston). For these models, power ranges from 4 to 20 Hp, while the air intake range goes from about 500 to about 2,400 L/minute.

Air compressors: how to choose the best compressor for you, your needs, and how to avoid making the wrong choice

First of all, when we decide to buy a compressor we have to ask some simple but fundamental questions:

- Why do I need to buy a compressor?

- What will its use be?

- For how long will I use it?

- How much do I want to spend?

The first thing we need to figure out is why we need a compressor and for what specific work we will be using it.

Is it for a hobby, small craft work, or DIY work?

If the purpose of buying a compressor is to use it in the home or in your workshop for small jobs such as blowing, tire inflating, or painting, we can safely think of a smaller size, less demanding, easy to use and easy to handle.

Various types of compressors

The characteristic that distinguishes compressors is the tank, its ability to accumulate aspirated air. There are medium-sized compressors that can be easily used and easily moved.

Compressors with tanks

Within the range of portable compressors, there are compact models with careful, innovative design with a medium-sized tank that allows for easy transport anywhere. One of the easiest to use products is without a doubt the Trolley compressor. When needs change and become more demanding, it is good to focus on more efficient models with higher performance, with a larger compressed air “reserve” and a more powerful motor that allows constant and continuous use over time.

Compressors with direct drive

In the vast majority of compressors mentioned so far, drive is direct. The pump unit is mounted directly on the motor in order to eliminate any type of power loss during operation. These are normally less expensive and easier to handle than those with belt drives, but they are suitable for sporadic and occasional use. Their use is almost always household or DIY.

Air compressor tank 24, 50, 100 L,

REMEZA Series SB4/S 1.8 – 2 – 2.4 HP 220/380V.

SB4/S series compressors are more suitable for tire inflation, blowing, and painting for household use, without problems during operation.

OIL-FREE two-cylinder air compressor tank 24, 50 L REMEZA mod. SBS

OLD/TWIN silenced model 1.0 – 1.5 HP 220V.

OIL-FREE two-cylinder air compressor TANDEM tank 100 L REMEZA mod. SBS/T

OLD/TWIN silenced series 1.0+1.0 – 1.5+1.5 HP 220V.

OIL-FREE air compressor tank 24, 50 L REMEZA mod. GMS/VS

Series with dryer 1.0 – 1.5 – 2.0 HP 220V.

OIL-FREE REMEZA series compressors are suitable for use in the Medical, Dentistry and Food fields, are recommended in the airbrush painting field, without any problems with oil residues in the air during operation.

Compressors with belt drive

More powerful compressors with large tanks instead have belt drives. They use different size pulleys that transfer motion from the motor to the pump and develop a very low speed rotation. This allows for use of compressed air in a stable and continuous way for long periods of time. There are silent compressor models that emit very low sound levels and are therefore very suitable for use in indoor or shared environments. Some large tank models have two quick release air jets that allow for simultaneous use of the compressor with two tools. Craftsmen, mechanics, body shop workers, and carpenters usually use these compressors for all phases of their work, generating great benefits and effective results.

Air compressor tank 24, 50 L, REMEZA

SB4/S series 2.0 – 3.0 HP 220/380V

Air compressor tank 100, 200 L, REMEZA

SB4/S series 4.0 – 5.5 – 10.0 –1 HP 380V

Air compressor tank 100, 270, 500 L, REMEZA

SB4/S series 4.0 – 5.5 – 10.0 –1 5.0 HP 380V

Vertical air compressor tank 100, 270 L, REMEZA

SB4/S series 3.0 – 4.0 – 5.0 – 7.0 HP 220/380V

TANDEM air compressor tank 500 L, REMEZA

SB4/F series 7.0+7.0 – 10.0+10.0 HP 380V

TANDEM air compressor tank 500 L, REMEZA

SB4/F series 7.0+7.0 – 10.0+10.0 HP 380V

Screw compressors

Screw compressors

The compressed air market is vast and there is an enormous supply by different manufacturers. There are two more common model types: screw and piston. In the latter, air compression is carried out through two “male/female” screws which rotate one toward the other and compress intake air. The volume depends on the length of the screw, its profile and the shape of the discharge hole. In this type of compressor, the drive shaft can reach high speeds with large accumulations of compressed air without large external dimensions.

Screw compressors are mainly used in the industrial sector (Remeza proposes the “start-stop” model for the auto and workshop parts sector), because they are designed to operate for long periods of time. In recent times, they are more used by body shops where new water paints are used, requiring a more efficient drying process than conventional ones with large amounts of consumed air. Screw compressors are mainly used in 24/7 applications, so they ensure constant and long-lasting operation. In the case of use of “start-stop” models, water residue can form inside the screw block which over time can transform in rust and hinder the proper operation of the block itself. Screw compressors guarantee compactness, durability, an improved flow/energy ratio and 10 to 15 hp cylinders are far superior to piston motors.

Lubricated Screw compressor tank 200 L, REMEZA

mod. BK “start/stop” open 3.0 – 4.0 HP 380V.

Lubricated Screw compressor tank 270 L, REMEZA

mod. BK 5.0 – 7.0 – 10.0 HP 380V.

Lubricated Screw compressor tank 500 L with dryer, REMEZA

mod. BKD 5.0 – 7.0 – 10.0 – 15.0 – 20.0 HP 380V.

Stationary lubricated Screw compressor tank, REMEZA

mod. BKE 20.0 – 25.0 – 30.0 – 40.0 – 50.0 – 60.0 – 45.0 – 100.0 HP 380V.

Piston compressors

Piston compressors

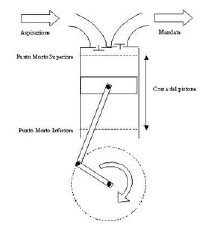

Piston compressors, on the other hand, are powered by a plunger that works in a piston with alternate motion imposed by a connecting rod connected to the drive shaft. They can be single-stage if air compression occurs in a single phase or two-stage when air compression takes place at two different times so as to obtain less air heating inside the cylinder. They are also distinguished as single-cylinder or two-cylinder, when the pump unit has one or two cylinders. The quantity of air accumulated is compressed in subsequent stages and air pressure takes on gradually growing value. The piston located inside the cylinder can be cast iron or aluminium: air is suctioned inside the cylinder by a suction valve which opens each time the pressure inside the duct is higher than that of the cylinder. Air is then expelled from the cylinder by means of the delivery valve, which opens when the cylinder pressure is higher than that of the duct.

How much air do I need?

A very important consideration that you will have to keep in mind before buying your compressor is related to the amount of air you need to adapt it to your needs. If, for example, you want to connect the compressor to a pneumatic tool, it is important to check the technical specifications on the ID plate to find out the air consumption expressed in litres per minute. If multiple tools are to be connected at the same time, it is necessary to add each one’s consumption to avoid having insufficient airflow when using them simultaneously. Often, the technical data sheets of the compressors report only information related to the volume of intake air per minute and not that delivered, which is always lower. We must however keep some basic parameters in mind to best understand what characteristics we need for the compressor we are going to buy:

- Direct drive compressors (coaxial) 30% less than the value of intake air

- Single-stage compressors with belt drive 25% less than the value of intake air

- Two-stage compressors with belt 15-20% less than the value of intake air

Furthermore, in the case of piston compressors, we must think about the so-called “Operating cycle” of the piston (Duty cycle) in order to obtain a more precise calculation: the piston has an alternating duty cycle in order to give pump unit components a chance to cool. This is calculated in 60% of the moving time and in 40% of the standstill time (basically, within an hour it works 36 minutes and remains stationary for 24).

Let’s take a look at an example:

– We take a direct drive compressor with a declared volume of intake air of

200 L/min

200 l/min x 30%= 60 l/min. of dispersed air

200 l/min – 60 l/min= 140 l/min of produced air

140 l/min x 0.60 (60% duty cycle) = 84 l/min actual air produced continuously

We can apply this calculation for practical use:

If we need to use the compressor to paint, we know that the paint gun needs 200 L/min of air, so the compressor will have an equal or slightly higher value of delivered air.

Below is a list of example values on air consumption based on the type of compressor:

Compressor

Direct drive

Single-stage belt

Two-stage belt

Dispersed air

30%

25%

20%

Division factor

0.70

0.75

0.80

Taking these indexes into account, we continue with the example

Air suctioned from the tool

200 L/min

Division factor

0.7

Duty Cycle

0.6

Intake air/min

286 L/min

Value of intake air

476 L/min

With this simple calculation, we have found that for continuous use of a gun suctioning 200 L/min of air, we will need a compressor with a suction air value of no less than 476 L/min. Changing the type of machine (belt drive, single-stage or two-stage), the required air volume tends to decrease: by this we can say that by choosing a two-way belt drive compressor, we will have a valid, efficient tool that is above all suited to our needs. Normally, manufacturers always specify the value of the intake air required by the various tools and equipment, so it will be extremely easy to calculate.

How long will you use the compressor?

Another very important factor to consider before purchasing the compressor is its usage time: if it is used only sporadically at home or for simple DIY projects, we recommend a direct drive compressor with 1.5 Hp motor power at 3 Hp. If you plan to use it more frequently, but not continuously, you can choose a direct drive or belt drive with motor power of at least 2 Hp. In the case of intensive and everyday use for work activities or for high level DIY, we recommend looking at models with belt drive and a motor of at least 3 Hp and over. Motor power is critical to compressor performance: if it is undersized with respect to its use, not only will mechanical parts deteriorate due to withstanding excessive operating stress, but it would also not be able to ensure the necessary performance, sending the compressor into “distress” and compromising its smooth operation. On the other hand, if the compressor is oversized with the performance at hand, you will be left with a “wasted,” costly and inadequate machine.